Leading innovators

In the automation of rebar processing

Our approach to Tailor made solutions

Step 1 Assessment of needs and goals

In a personal conversation we discuss the company's goals and needs.

By looking at the needed production size, level of automation, used software and drawings of the factory.

Step 2 New factory layout

The desired situation coming from the initial conversation is translated into a new developed drawing of the factory. Next to the already existing machines our tailor-made drawing shows the new machines with their logistic options. Together with the customer the advantages and options are discussed and adjusted if needed.

Step 3 Offering of the machines

After confirming the new drawing, a suitable quote is made. Showing details and offering numerous options to fully customise the installation as needed.

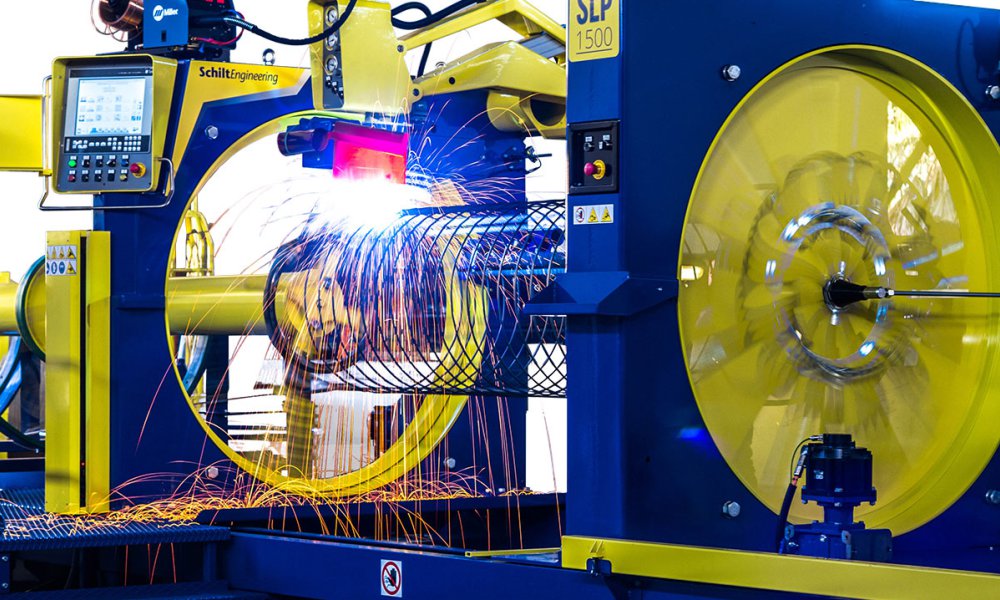

Step 4 Production of machinery

Production of the machines is then done in-house at our facility in Schoonhoven.

The inhouse production process ensures optimized communication between departments, resulting in quality machinery.

Step 5 Machine installation

Specialized engineers ensure adequate installation of machinery around the world. Before installation the machines are tested, rresulting in optimized installation times and minimal downtime of production. After installation operators are trained to safely operate the new machinery.

Step 6 Aftersales

Our machines are accessible by internet, allowing for online technical support if needed. Our technical support team is also available for questions and quick delivery of spare parts.